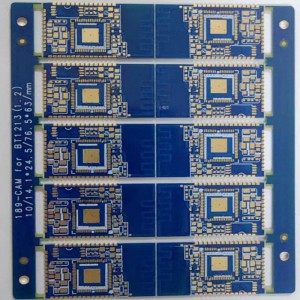

Pcb prototype pcb samaynta maaskaro alxanka buluuga ah oo ka dahaadhay godad nus ah

Tilmaamaha Alaabta:

| Qalabka Saldhigga: | FR4 TG140 |

| Dhumucda PCB: | 1.0+/-10% mm |

| Tirada lakabka: | 2L |

| Dhumucda Copper: | 1/1 oz |

| Daaweynta dusha sare: | ENIG 2U" |

| Maaskarada alxanka: | buluug dhalaalaya |

| Shaashada xariirta: | Caddaan |

| Habka gaarka ah: | Pth nus godadka geesaha |

Codsiga

PCB-daloollada nuska ah waxa loola jeedaa qodista labaad iyo habka qaabaynta ka dib markii godka kowaad la qoday, iyo ugu dambeyntii kala bar godka birta ah ayaa loo hayaa. Ujeedada ayaa ah in si toos ah loo dhufto cidhifka godka cidhifka ugu weyn si loo badbaadiyo isku xirka iyo booska, oo inta badan ka muuqda wareegyada calaamadaha.

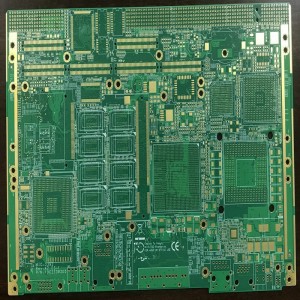

Looxyada wareegga nuska ah waxaa badanaa loo isticmaalaa in lagu dhejiyo qaybaha elektiroonigga ah ee cufnaanta sare leh, sida aaladaha mobilada, saacadaha smart, qalabka caafimaadka, qalabka maqalka iyo muuqaalka, iwm.

Daloolka nuska ah ee aan dahaadhka ahayn ee cidhifyada PCB-ga waa mid ka mid ah walxaha naqshadaynta ee sida caadiga ah loo isticmaalo geeddi-socodka wax-soo-saarka PCB-ga, shaqadeeda ugu weyni waa hagaajinta PCB-ga. Habka wax-soo-saarka guddiga PCB-ga, adigoo ka tagaya godadka kala bar meelaha qaarkood ee cidhifka guddiga PCB-ga, guddiga PCB waxaa lagu hagaajin karaa qalabka ama guriga oo leh boolal. Isla mar ahaantaana, inta lagu guda jiro habka isu-ururinta guddiga PCB, daloolka nuska ah wuxuu kaloo caawiyaa in la dhigo oo la isku toosiyo guddiga PCB si loo hubiyo saxnaanta iyo xasilloonida alaabta ugu dambeysa.

Daloolka nuska ah ee lagu dhejiyay dhinaca guddiga wareegga waa in la hagaajiyo isku halaynta isku xirka dhinaca guddiga. Caadi ahaan, ka dib marka guddiga wareegga daabacan (PCB) la gooyo, lakabka naxaasta ah ee daboolan ee cidhifka ayaa soo muuqan doona, kaas oo u nugul oksaydhka iyo daxalka. Si loo xalliyo dhibaatadan, lakabka naxaasta ah ayaa inta badan lagu dahaadhay lakabka ilaalinta iyada oo loo yaqaan 'electroplating cidhifka guddiga godka nuska ah si loo hagaajiyo caabbinta oksaydhka iyo caabbinta daxalka, waxayna sidoo kale kordhin kartaa aagga alxanka waxayna hagaajinaysaa kalsoonida isku xirka.

Inta lagu jiro habka farsamaynta, sida loo xakameeyo tayada alaabta ka dib samaynta godadka semi-metalized ee cidhifka looxa, sida qodxaha naxaasta ah ee derbiga daloolka, iwm, had iyo jeer waxay ahayd dhibaato adag habka wax soo saarka. Looxa noocan oo kale ah oo leh saf dhan oo godad bir bir ah ka samaysan ayaa looxa PCB waxaa lagu gartaa dhexroorka dalool yar, waxaana inta badan loo isticmaalaa guddiga gabadha ee guddiga hooyada. Daloolladaas, waxa lagu wada alxanayaa looxa hooyada iyo biinanka qaybaha. Marka la iibinayo, waxay u horseedi doontaa alxanka daciifka ah, alxanka beenta ah, iyo isku xirka gaaban ee dhexda labada biin.

FAQs

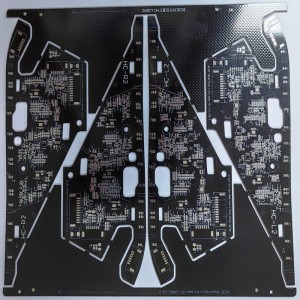

Waxaa laga yaabaa inay faa'iido leedahay in la dhigo godad dhejisan (PTH) geesaha looxa. Tusaale ahaan marka aad rabto in aad laba PCB's ku iibiso xagal 90° ah ama marka aad PCB ka iibinayso daasad bir ah.

Tusaale ahaan, isku-darka modules-ka-koontarool ee adag ee PCB-yada caadiga ah, si gaar ah loo qorsheeyay.Codsiyada dheeraadka ah ayaa la soo bandhigay, HF ama modules dhoobada kuwaas oo lagu iibiyo sabuuradda wareegga daabacan ee saldhigga ah.

Qodista- dalool lagu dahaadhay (PTH) - dahaadhid guddi - wareejinta sawirka - dajinta hannaankii -pth nuska daloolka - xariijimaha - etching - maaskaro alxan - silkscreen - daaweynta dusha.

1. Dhexroorka ≥0.6MM;

2. Masaafada u dhaxaysa cidhifka daloolka ≥0.6MM;

3. Baaxadda giraanta etching waxay u baahan tahay 0.25mm;

God nusku waa hannaan gaar ah. Si loo hubiyo in ay jirto naxaas godka ku jira, waa in ay marka hore wax shiiddo ka hor inta aan la dhigin habka naxaasta. PCB-ga guud ee godka nusku aad buu u yar yahay, markaa qiimihiisa ayaa ka qaalisan PCB-ga caadiga ah.