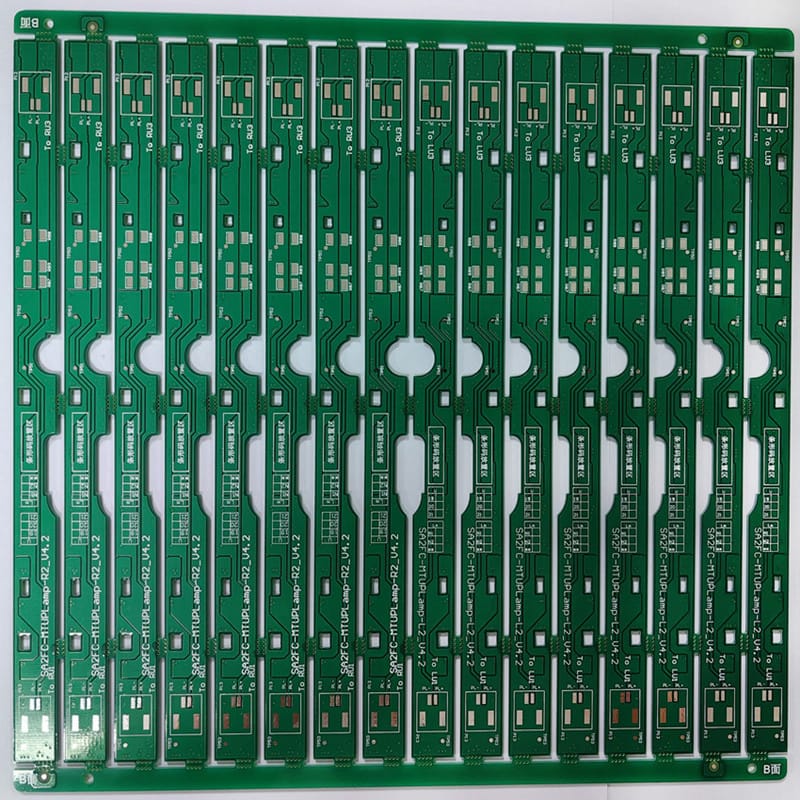

Prototype board pcb laba geesood ah FR4 TG140 impedance kontoroolka PCB

Tilmaamaha Alaabta:

| Qalabka Saldhigga: | FR4 TG140 |

| Dhumucda PCB: | 1.6+/-10%mm |

| Tirada lakabka: | 2L |

| Dhumucda Copper: | 1/1 oz |

| Daaweynta dusha sare: | HASL-LF |

| Maaskarada alxanka: | Cagaar dhalaalaya |

| Shaashada xariirta: | Caddaan |

| Habka gaarka ah: | Heerka |

Codsiga

Looxyada wareegga ee leh impedance la kontoroolo waxay leeyihiin sifooyinka soo socda:

1. Si adag u xakamee habka wax soo saarka ee guddiga wareegga, oo ay ku jiraan xulashada alaabta, fiilooyinka daabacan, kala dheereynta lakabka, iwm, si loo hubiyo xasiloonida impedance ee wareegga;

2. Isticmaal qalabyada naqshadaynta PCB ee gaarka ah si aad u hubiso in caqabadu buuxisay shuruudaha naqshadaynta;

3. Dhammaan qaabka iyo habaynta PCB, isticmaal jidka ugu gaaban oo yaree foorarsiga si aad u hubiso xasilloonida xannibaadda;

4. Yaree is-goysyada u dhexeeya xariiqda signalka iyo xadhka korontada iyo xariiqda dhulka, oo yare is-dhaafsiga iyo faragelinta xariiqda ishaarka;

5. Isticmaal tignoolajiyada impedance-ka ee ku habboon khadka gudbinta calaamadaha xawaaraha sare si loo hubiyo nadiifnimada iyo xasilloonida calaamadda;

6. Isticmaal tignoolajiyada isku xirka interlayer si loo yareeyo buuqa isku xidha iyo shucaaca korantada;

7. Marka loo eego shuruudaha impedance ee kala duwan, dooro dhumucda lakabka ku habboon, ballaca xariiqda, kala dheereynta khadka iyo joogtada ah ee dielectric;

8. Isticmaal qalab tijaabo ah oo gaar ah si aad u sameyso tijaabada impedance ee guddiga wareegga si aad u hubiso in xaddidaadaha impedance ay buuxiyaan shuruudaha naqshadeynta.

Waa maxay sababta xakamaynta impedance caadiga ah u noqon kartaa oo kaliya 10% leexasho?

Saaxiibo badan ayaa runtii rajeynaya in xannibaadda lagu xakameyn karo 5%, xitaa waxaan maqlay shuruudaha 2.5% impedance. Dhab ahaantii, nidaamka xakamaynta impedance waa 10% leexashada, wax yar oo adag, wuxuu gaari karaa 8%, waxaa jira sababo badan:

1, leexashada alaabta saxanka lafteeda

2. leexashada cuncunka inta lagu jiro habaynta PCB

3. Heerka qulqulka qulqulka ee uu keeno lamination inta lagu jiro habaynta PCB

4. Xawaaraha sare, roughage dusha sare ee bireed naxaas ah, saamaynta fiber galaas PP, iyo saamaynta soo noqnoqda DF ee warbaahinta waa in ay fahmaan impedance.

Xagee loo isticmaalaa looxyada wareegyada leh shuruudaha impedance guud ahaan?

Looxyada wareegyada leh shuruudaha impedance waxaa inta badan loo isticmaalaa gudbinta signallada xawaaraha sare leh, sida gudbinta signalka dhijitaalka ah ee xawaaraha sare leh, gudbinta signalka soo noqnoqda raadiyaha iyo gudbinta signalka hirarka millimitirka. Tani waa sababta oo ah xannibaadda guddiga wareegga waxay la xiriirtaa xawaaraha gudbinta iyo xasilloonida calaamadda. Haddii naqshadeynta impedance ay tahay mid aan caqli-gal ahayn, waxay saameyn doontaa tayada gudbinta calaamadda waxayna xitaa sababi doontaa luminta calaamadaha. Sidaa darteed, waqtiyada u baahan tayada gudbinta calaamadaha sare, badanaa waa lagama maarmaan in la isticmaalo looxyada wareegga oo leh shuruudaha impedance.

FAQs

Impedance waxay cabbirtaa diidmada wareegga korantada marka hadda beddelka ah lagu dabaqo. Waa isku dhafka awoodda iyo kicinta wareegga korantada ee soo noqnoqda sare. Culayska waxaa lagu cabbiraa Ohms, si la mid ah iska caabinta.

Waxyaabo dhowr ah oo saameeya xakamaynta impedance inta lagu jiro naqshadeynta PCB waxaa ka mid ah ballaca raadraaca, dhumucda naxaasta, dhumucda dielectric iyo joogtada ah dielectric.

1) Erku wuxuu u dhigmaa si ka duwan qiimaha impedance

2) Dhumucda dielectric waxay u dhigantaa qiimaha impedance

3) Balaca xariiqu waxa uu u dhigma si ka duwan qiimaha impedance

4) Dhumucdiisuna waxay tahay naxaasta si ka soo horjeeda qiimaha impedance

5) Kala dheeraynta khadadka waxay u dhigantaa qiimaha impedance ( impedance kala duwan)

6) Dhumucda iska caabbinta alxanka waxay la mid tahay qiimaha impedance

Codsiyada soo noqnoqda ee sarreeya ee u dhigma xannibaadda raadadka PCB ayaa muhiim u ah ilaalinta daacadnimada xogta iyo caddaynta calaamadaha. Haddii cilad-celinta raadraaca PCB-ga ee isku xidha laba qaybood aanu u dhigmin cilladda sifada qaybaha, waxa laga yaabaa inay kordhiso wakhtiyada beddelka ee aaladda ama wareegga.

Cidhiidhiga kelida ah ee dhammaatay, is-hortaagga kala duwan, is-hortaagga Coplanar iyo Stripline Lammaannada Broadside